The magic behind your AC, refrigerator, or freezer is a substance known as refrigerant. In modern day life, refrigerants stand out as indispensable but there are several environmental and safety concerns arising. If you are wondering about the meaning of refrigerant, its types, refrigeration cycle, and possible environmental and safety concerns, all these things will be answered in this article.

What is Refrigerant?

Refrigerant is a conductive liquid or vapor used in the refrigeration or freezing technology cycle of an air conditioning system to provide cooling by absorbing heat from the room or surroundings.

What Color is Refrigerant?

Refrigerants in their natural condition are colorless and do not have any odor. However, when a refrigerant leaks, it might appear slightly pale yellow. Most refrigerants are colorless gases when leaked into the atmosphere. But still, there are specific dyes that can be added by the manufacturer for leak tracing. These dyes can vary from green to red.

What Does Refrigerant Smell Like?

Freon travels through closed copper coils in the units, but there are possibilities of leakages which might leave you wondering how does it smell like. Generally, refrigerants tend to have a sweet, mild smell-but rather more of the older varieties like Freon (R12). Most modern types of refrigerants don’t smell at all; it’s almost impossible their leaks could be noticed without certain equipment. On the off-chance, one smells something sweet or chemical-like from the cooling, which may mean a leak is happening with the refrigerant.

Is Refrigerant Flammable?

The question of whether refrigerant is flammable is a hot debate.

Yes, some refrigerants are flammable, while others are non-flammable. Refrigerants are categorized into different safety classes based on their flammability and toxicity:

1. Class A1 (Non-flammable) – These refrigerants are considered safe and non-flammable under normal operating conditions. Common examples include R-134a and R-22. However, these older refrigerants are often being phased out due to environmental concerns.

2. Class A2, A2L, and A3 (Flammable) – Refrigerants in these classes vary in flammability:

a. A2L refrigerants, like R-32 and R-1234yf, are mildly flammable.

b. A3 refrigerants, such as R-290 (propane), are highly flammable and are typically used in smaller systems or controlled environments.

How Many Pounds of Refrigerant per Ton?

Most conditioners are known to use 2-4 pounds of refrigerant per ton per the cooling capacity as shown by an analysis from Seattle.

How Much is Refrigerant per Pound?

The price of a refrigerant will vary greatly depending on factors such as type of refrigerant, regulations, supply and demand, production costs, packaging and volume etc. For examples, R-22, R-410A, R-32 costs are $90-$125, $50 to $90, $10 to $20 per pound on average.

Types of Refrigerants

There are two types of refrigerant available, such as Primary refrigerants and Secondary refrigerants.

1. Primary Refrigerants:

Primary refrigerants are working fluids that directly used in refrigeration systems, such as in vapor compression and vapor absorption systems. These fluids provide cooling by undergoing a phase change process in the evaporator, effectively absorbing heat and creating a cooling effect.

Types of Primary Refrigerants:

1. Halocarbon Refrigerants

They are synthetically produced and are known as the Freon group of refrigerants. These refrigerants are now banned due to bad effects on the environment.

Examples: Chlorine, Fluorine, and Carbon atoms.

| Refrigerant name | Chemical name | Chemical formula | ODP | GWP |

| R-11 | Tricholormonofluoromethane | CCl3F | 1 | 4000 |

| R-12 | Dichlorofluoromethane | CCl2F2 | 1 | 8500 |

| R-13 | Monochlorotrifluoromethane | CClF3 | 1 | 13900 |

| R-14 | Carbontetrafluoride | CF4 | 0 | 6630 |

| R-21 | dichloromonofluromethane | CHCl2F | .04 | 151 |

| R-22 | Monochlorodifluoromethane | CHCLF2 | 0.05 | 1810 |

2. Azeotrope Refrigerants

They are a mixture of different refrigerants which cannot be separated under pressure and temperature. They are designated by 500 series.

Examples: R-500 which is a mixture of 73.8% R-12 and 26.2% R-152

| Refrigerant name | Chemical name | Composition or Chemical formula | ODP | GWP |

| R-502 | R-22/R-115 (48.8%/51.2%) | .33 | 5600 | |

| R-507 | Dichlorofluoromethane | R-125/R-143a (50%/50%) | 0 | 4000 |

3. Hydrocarbon Refrigerants

Hydrocarbons are consist of hydrogen and carbon. They possess satisfied thermodynamic properties but are highly flammable and explosive.

Examples: Ethane, Propane, Butane, and Ethylene.

| Refrigerant name | Chemical name | Composition or Chemical formula | ODP | GWP |

| R-170 | Ethane | CH3CH3 | 0 | 6 |

| R-290 | Propane | CH3CH2CH3 | 0 | 3 |

| R-600 | Isobutane | CH(CH3)2CH3 | 0 | 3 |

| R-1150 | Ethylene | C₂H₄ | 0 | 3.7 |

4. Inorganic Refrigerants

They were exclusively used before the introduction of halocarbon refrigerants. However, they are still in use because of their inherent thermodynamic and physical properties.

Examples: Ammonia, Air, Carbon dioxide, Sulfur dioxide, and Water.

2. Secondary Refrigerants:

Secondary refrigerants are working liquids used to transfer thermal energy from one place to another. They are referred to as brines or antifreezes. These fluids do not undergo a phase change but are essential for efficiently moving heat within a cooling system.

Example: Brine water (Mixture of salt and water), water and air.

What is the Difference Between Primary and Secondary Refrigerant?

| Primary Refrigerant | Secondary Refrigerant |

| It takes part directly in the refrigeration system | It doesn’t take part directly in the refrigeration system |

| It changes its phase | Anti-freeze is required |

| It is expensive | It is cheap |

| Require less refrigerant | Require more refrigerant than primary refrigerant |

| It may or may not be corrosive | No anti-freeze is required |

| May or may not be corrosive | usually corrosive |

| Examples: HFC-134a, HC-600a, HCFC-22, CFC-12 | Examples: Brine water (the mixture of salt and water), air, and water. |

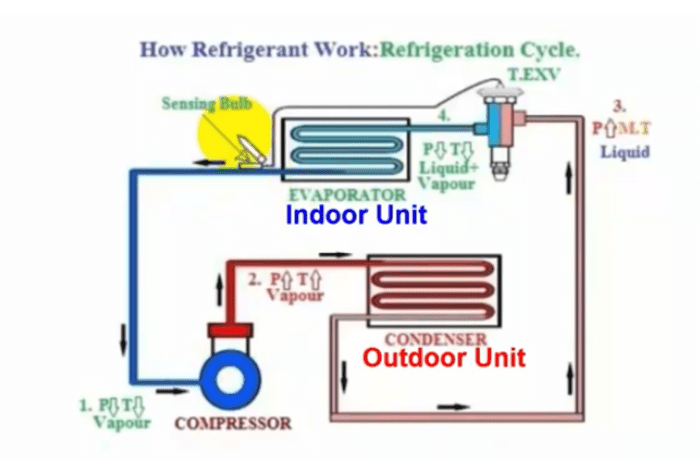

How Does Refrigerant Work in a Refrigeration Cycle? (With Refrigerant Cycle Diagram)

In the refrigeration process, refrigerant go through four steps, including compression, condensation, expansion, and evaporation to complete a refrigeration cycle. Here’s a step-by-step explanation of how these four steps work in the refrigeration cycle:

Step 1: Compression

This is the first step of a refrigeration cycle. When the low-pressure (L.P) vapor refrigerant at low temperature (L.T) comes from the evaporator and enters the compressor, the compressor compresses the vapor refrigerant to convert it into high-pressure (H.P) and high-temperature (H.T) vapor refrigerant, which enters the condenser.

Step 2: Condensation

The condensation process in a refrigeration cycle occurs in the condenser. It is the first one of the two heat exchangers that participate in the refrigeration cycle. When the compressor supplies the high-pressure (H.P) and high-temperature (H.T) vapor refrigerant to the condenser, it starts condensing the refrigerant until it changes into high-pressure (H.P) and medium-temperature (M.T) liquid refrigerant.

Tips: The Condenser unit of speed type, window type, and packaged type AC is cooled by air, the condenser unit of the air chiller is cooled by air, and the condenser unit of the water chiller is cooled by water.

Step 3: Expansion

When this high-pressure (H.P) and medium-temperature (M.T) liquid refrigerant coming from the condenser is passed through a very tiny hole of the expansion valve, this liquid refrigerant changes into a low-pressure (L.P) and low-temperature (L.T) liquid and vapor refrigerant. The reason is when the high-pressure vapor is passed through a small hole into a wide pipe or more space, the pressure of the refrigerant is reduced. And due to the decrease in pressure, the temperature also decreases.

Step 4: Evaporation

Evaporation is the last step of the refrigeration cycle that refers to the phase where the refrigerant absorbs heat and changes from a liquid to a vapor. This process happens in the evaporator unit which is one of the key components of the refrigeration system. This evaporator is called the second heat exchanger like the condenser unit that perform role in the refrigeration cycle.

Here’s How the Evaporator Works:

When the refrigerant comes from expansion as a low-pressure liquid and vapor enters the evaporator at a low temperature, it absorbs heat from the surrounding air or space being cooled. As the refrigerant absorbs heat, it changes from a liquid state to a vapor. This phase change occurs at a constant temperature, where the refrigerant continues absorbing heat without increasing its temperature.

Once the refrigerant has fully evaporated into a low-pressure vapor, it is sent to the compressor, ready to continue the refrigeration cycle.

Properties of an Ideal Refrigerant: How to Identify a Good Refrigerant?

Choosing the right refrigerant is essential for the efficiency, safety, and longevity of any refrigeration or air conditioning system. A good refrigerant should meet a specific set of criteria that ensure optimal performance while minimizing environmental and safety concerns. Here are the key properties to look for when identifying an ideal refrigerant:

- Non-toxic: The refrigerant must be non-toxic. Safety is a priority, and an ideal refrigerant should not pose health risks.

- Non-flammable and not explosive: For safety, the refrigerant should be stable under normal operating conditions.

- Low cost: The cost of the refrigerant should be low as cost-effectiveness is important for widespread use.

- Readily available: It should be readily available as accessibility is key for practical application.

- Minimal global warming impact: Environmental sustainability is crucial, so refrigerants with low Global Warming Potential (GWP) and no ozone depletion potential (ODP) are preferred.

- Low boiling point: The refrigerant should have a low boiling point. A low boiling point helps the refrigerant evaporate easily, absorbing heat efficiently.

- Non-corrosive: The refrigerant should not react with the materials of the refrigeration system, preventing damage.

- Operated at positive pressure: Refrigerants should be operated at positive pressure. Operating at positive pressures helps prevent the ingress of air and moisture into the system.

- High electrical resistance: Refrigerant should have high electrical resistance. This is less critical unless the refrigerant comes into contact with electrical components. For most systems, dielectric properties are important in specific applications, like motor cooling.

- Moisture resistant: Refrigerant should be moisture resistant as moisture can cause freezing and damage in the system, so the refrigerant should be moisture-resistant.

- Mixes easily with oil: It must be able to mix with lubricant oils without losing efficiency.

- Liquefies easily at moderate temperatures and pressures: This ensures efficient condensation and evaporation.

- Detect leaks easily: The refrigerant should be easy to detect if a leak occurs, ensuring safety and maintaining system efficiency.

- High lean temperature: This might be a misunderstanding. Instead, a refrigerant should have a high critical temperature, above which it can’t be condensed into a liquid.

- Small volume of vapors: The volume of refrigerant vapors should be as small as possible. A refrigerant that requires less volume for the same cooling effect is more efficient.

- Minimal pressure difference between evaporation and condensation: The pressure difference between the two in evaporating and condensing should be less. Lower pressure differences reduce the work required by the compressor, improving efficiency.

- High thermal conductivity: The thermal conductivity of the refrigerant should be high as high thermal conductivity improves heat transfer.

- Low freezing point: The freezing point of the refrigerant should be lower than any temperature during the refrigeration process.

What is Eco-Friendly Refrigerant?

An eco-friendly refrigerant is a type of refrigerant that has minimal environmental impact, particularly in terms of its effects on global warming and ozone layer depletion. The key characteristics of eco-friendly refrigerants are:

- Low Global Warming Potential (GWP): GWP measures how much heat a refrigerant traps in the atmosphere over a specific period, relative to carbon dioxide (CO₂). Eco-friendly refrigerants have a low GWP, meaning they contribute less to global warming.

- Zero Ozone Depletion Potential (ODP): ODP measures the ability of a substance to deplete the ozone layer. Eco-friendly refrigerants have zero or very low ODP, meaning they do not harm the ozone layer.

- Energy Efficiency: Many eco-friendly refrigerants are also highly energy-efficient, reducing the energy consumption of cooling systems, which indirectly lowers greenhouse gas emissions.

In essence, eco-friendly refrigerants are designed to minimize environmental harm while still providing effective cooling.

What are Some of the Good and Environmentally Friendly Refrigerants?

Environment-friendly refrigerants are classified into four categories. They are Natural refrigerants, Hydrofluoroolefins (HFOS), Hydrofluorocarbons (HFCs), and Hydrofluoroethers (HFEs).

Natural Refrigerants:

- Carbon dioxide (CO2): Also known as R-744, CO₂ is a naturally occurring refrigerant with zero Ozone Depletion Potential (ODP) and a very low Global Warming Potential (GWP). It is commonly used in commercial and industrial refrigeration.

- Ammonia (NH3): Also referred to as R-717, ammonia is a natural refrigerant with zero ODP and a GWP of zero. It is widely used in large industrial refrigeration systems due to its high efficiency. However, it is toxic and requires proper safety measures.

- Hydrocarbons (HCs): These include refrigerants like Propane (R-290) and Isobutane (R-600a). Hydrocarbons are natural refrigerants with very low GWP and zero ODP. They are frequently used in household refrigeration and air conditioning but are flammable, so safety measures are necessary.

Hydrofluoroolefins Refrigerants (HFOS)

- R-1234yf: It is considered eco-friendly because of its low GWP (4) and zero ODP. R-1234yf is seen as a more sustainable alternative to older refrigerants like R-134a and is widely used in car air conditioning systems. However, it is still a synthetic refrigerant, unlike natural refrigerants such as CO₂ or ammonia.

- R-1234ze: It is also considered eco-friendly. It has an extremely low GWP of less than 1, zero ODP. It is highly energy-efficient and is used in systems such as air conditioning, refrigeration, and even foam-blowing applications. This efficiency helps in reducing overall energy consumption, contributing to reduced greenhouse gas emissions.

- R-1243zf: It is an eco-friendly refrigerant with a low Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP). It belongs to the hydrofluoroolefin (HFO) family and is a more sustainable alternative to traditional refrigerants like R-134a.

Hydrofluorocarbons Refrigerants (HFCs)

- HFC-152 or R-152

- HFC-32 or R-32

- R-245fa

Hydrofluoroethers Refrigerants (HFEs)

- HFE-347mcc

- HFE-245fa2

- HFE-245cb2

Bad Effects of Using Refrigerants on the Environment

Refrigerants, especially older and certain commonly used types, can have several negative effects on the environment. Here are some of the major environmental impacts:

1. Ozone Layer Depletion

Older refrigerants like chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are notorious for damaging the ozone layer. The ozone layer protects the Earth from harmful ultraviolet (UV) radiation. When CFCs and HCFCs are released into the atmosphere, they break down and release chlorine atoms, which then react with ozone molecules, depleting the ozone layer. This depletion can lead to increased UV radiation reaching the Earth’s surface, resulting in:

- Increased rates of skin cancer and cataracts in humans.

- Negative impacts on ecosystems, including marine life and plants.

2. Global Warming

Many modern refrigerants, especially hydrofluorocarbons (HFCs), do not deplete the ozone layer but have a high global warming potential (GWP). When released into the atmosphere, they trap heat more effectively than carbon dioxide, contributing significantly to global warming. This can lead to:

- Rising global temperatures.

- Melting polar ice caps and glaciers, contributing to sea-level rise.

- More extreme weather events, such as hurricanes and heatwaves.

3. Energy Consumption and Carbon Footprint

Refrigeration and air conditioning systems often use significant amounts of energy, much of which is generated by burning fossil fuels. The use of inefficient refrigerants or systems can:

- Increase the carbon footprint of buildings and industries.

- Contribute indirectly to climate change by increasing greenhouse gas emissions through energy use.

4. Air and Water Pollution

In some cases, refrigerants can leak or be improperly disposed of, contaminating soil, water bodies, and air. This pollution can:

- Harm aquatic ecosystems.

- Lead to the accumulation of toxic substances in the food chain.

- Impact human health, causing respiratory and other issues.

5. Resource Depletion

Producing, transporting, and disposing of refrigerants can consume large amounts of natural resources, including energy, minerals, and raw materials. The inefficient use of these resources contributes to environmental degradation and depletion of non-renewable resources.

Laws to Know Before Using Refrigerant

Before using refrigerants, several important laws and regulations must be considered. The Montreal Protocol phases out ozone-depleting substances like CFCs and HCFCs, while the Kigali Amendment targets the reduction of high-global-warming-potential (GWP) HFCs to mitigate climate change. In the U.S., the Clean Air Act (Section 608) requires EPA certification for anyone handling refrigerants, prohibits venting, and mandates leak detection and repairs. The EU F-Gas Regulation also focuses on reducing HFC emissions, enforcing leak prevention, and requiring proper certification for technicians.

Safety is another key concern, with OSHA setting guidelines for safe refrigerant handling to prevent chemical exposure. Standards like ISO 817 classify refrigerants based on toxicity and flammability, while ASHRAE Standards 15 and 34 govern the safe design, installation, and operation of refrigeration systems. Following these laws helps ensure proper refrigerant management, reduces environmental harm, and avoids legal penalties.

Frequently Asked Questions

How does a refrigerant leak smell?

Refrigerants typically have little to no odor, but under certain circumstances, you might detect a faint smell. Different refrigerants may have different scents:

- CFCs and HCFCs: These refrigerants are often odorless, but if they are leaking, they may have a faintly sweet ethereal odor.

- HFCs: Hydrofluorocarbon (HFC) refrigerants are typically colorless and odorless gases. When an HFC refrigerant leaks, you generally won’t notice any distinct smell. However, large leaks can sometimes cause a slight chemical odor due to the presence of trace lubricants or additives used with the refrigerant.

- Ammonia (NH₃): Ammonia (NH₃) refrigerant has a very distinct, strong, and pungent odor, similar to the smell of household cleaning products that contain ammonia.

- Propane (R-290): Propane (R-290) refrigerant has a faint, mild smell that is generally described as slightly sweet and similar to natural gas. However, in its pure form, propane is odorless. To make leaks detectable, manufacturers typically add an odorant (like ethyl mercaptan), which gives it a strong, unpleasant odor similar to rotten eggs or sulfur.

Can hydrocarbon refrigerants be used as a retrofit refrigerants?

Yes, hydrocarbon refrigerants like Isobutane (R-600a) and Propane (R-290) can be used as retrofit refrigerants, but their flammability poses safety risks. Retrofitting systems designed for non-flammable refrigerants may require modifications, such as adjusting components to handle the flammable nature of hydrocarbons. Legal regulations also vary by region, and retrofitting should be performed by certified technicians. Despite the risks, hydrocarbons are efficient and eco-friendly, with low Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP), making them a sustainable choice.

Leave a Review